Temperature Sensor Cable SL3000/5000

Avoid spoilage in your grain by detecting hotspots

Our Temperature cables are what you need to have precise and regular updates on how the temperature is evolving inside your silo or bulk storage facility. Thanks to years of in-house experience and development we can offer you a solid solution to monitor the temperature of your grain. The cables are designed to be used in the toughest environments and can be customized in length to fit in every different silo or storage facility.

There are many ways to attach the cables to your silo and we are, as always, very happy to support you in the process. However, the solution we recommend is the Roof Suspension and you can find more information about it here

The key functions and benefits are

Customized Sensor Lines from 1 to 80 metres in length

Durable antistatic construction for high loads and certified for ATEX Zone 20/21/22

Number of sensors on request, standard distance is every 1, 2 or 3 metres

Simple and easy installation – only two wires to connect

No temperature drift over time

Maintenance-free

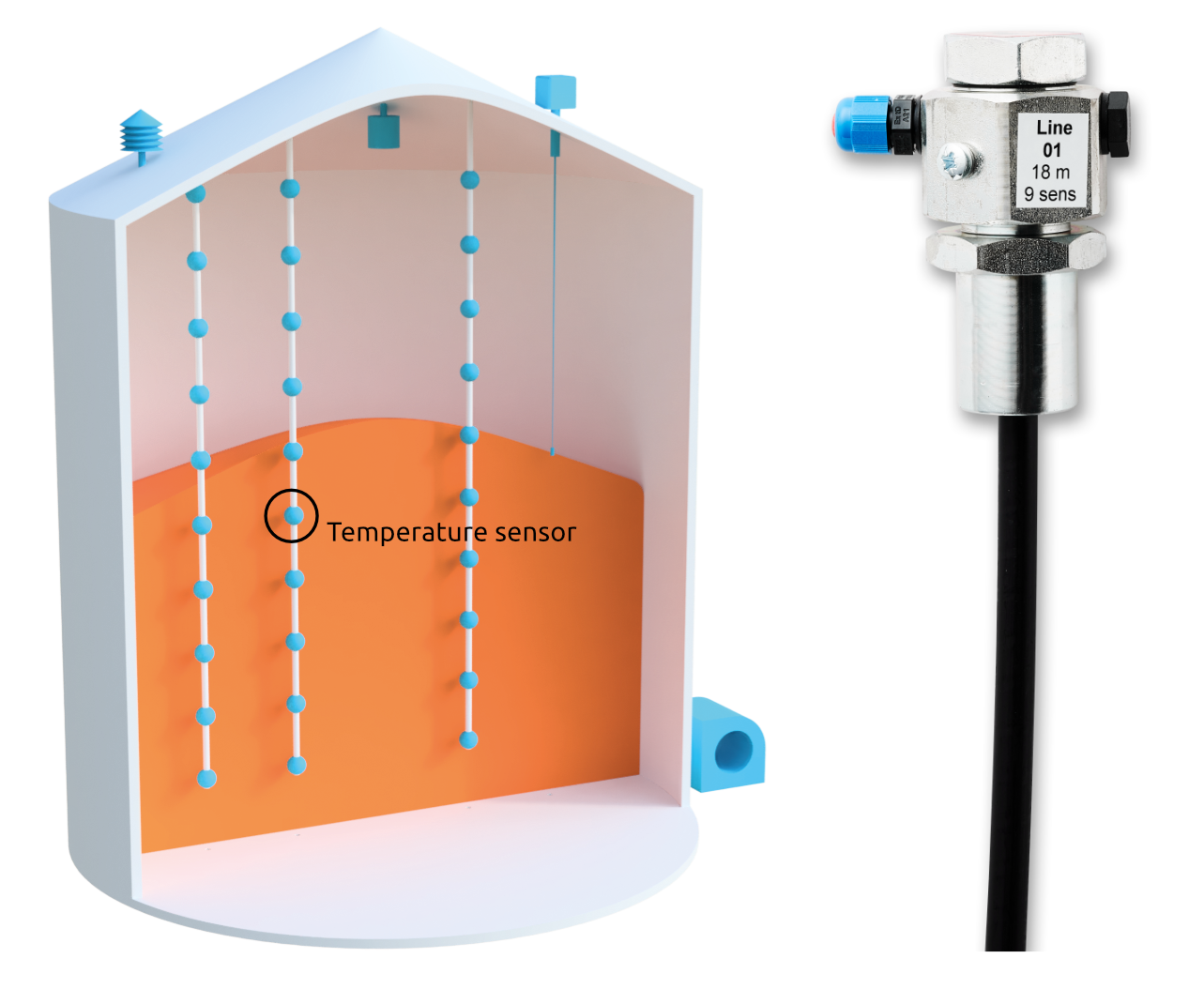

Placing the Sensor Cable inside the silo

We recommend placing the Sensor Lines in a pattern as shown by the orange dots in the figure on the right. The location and the number of the cables depend on the diameter of the silo.

A well-placed grid of sensors along with frequent logging and tracking are the most important elements of a complete silo-monitoring system.

Technical Specifications

Temperature Sensor Cable: Diameters Ø10,8mm

Maximum Cable length: 50m/80m

Sensor Temperature range: -20°C to +80°C

Ex Temperature Range: -20°C to +40°C

Resolution: Sensor placement 1m, 2m or 3m

Sensor per Cable: Unlimited

Silo roof mounting: Hook, roof suspension place, etc.

Silo floor mounting: Eye bolt

Tensile strength: 3600kg/7500kg

ATEX Ex-marking: II 1 D Ex ia IIIC T 150°C Da IP66

Learn which bin monitoring system fits your needs.

AgroLog Manager Software

Our AgroLog Manager software will process all information collected by the sensors and display them using a friendly and intuitive UI. Through our software, you will know about the smallest change in your storage facility and you will be informed about any critical issue to react immediately and avoid any damages to your stored crops.

How the software works

Access the system anytime and anywhere using PC, smartphone or tablet etc.

Increase safety. With one system you can control multiple sites from anywhere in the world

Centralised system. Achieves high security and protection of data while being easy to manage and maintain

Use the automated reports. Save work time by letting the software generate valuable insights for you

No software, backup or server maintenance as we handle this for you. We guarantee the safety of your data

Temperature Monitoring

Gain a complete understanding of your grain storage with a 3D representation of each bin or silo. This intuitive view allows you to pinpoint the exact location of every temperature sensor within your facility.

Color-coded temperature readings provide instant insight into the current state of your grain. Quickly identify areas with potential issues based on the intuitive color scheme.

Pre-defined alarm thresholds automatically trigger alerts when temperatures exceed safe limits. This allows for prompt intervention and helps prevent grain spoilage.

Maintain grain quality by staying ahead of temperature fluctuations, you can take proactive measures to preserve grain quality and minimize spoilage risks.

Early detection of temperature spikes allows for quick intervention, potentially saving you significant financial losses.

See AgroLog Manager in Action

Want to see how simple and intuitive AgroLog Manager really is?

Watch this quick video to see the software’s 3D bin view, real-time temperature readings, and automatic alerts in action—so you can detect issues early and keep your stored crops safe.